Global learnings on the impact of ‘transient’ risks on Concentrated Solar Power tower systems are driving improved storage tank piping and all-welding techniques, experts told New Energy Update.

In a bid to accelerate deployment, the US National Renewable Energy Laboratory (NREL) published June 12 the world’s first best practices report for CSP plants.

NREL researchers analyzed data and feedback from 80% of CSP plants operating worldwide, covering parabolic trough and less mature CSP tower and storage technologies.

The report sets out a number of key learnings across project management, plant design, and operations.

A key area of concern for CSP investors is the efficiency and reliability of higher temperature CSP towers, which use molten salt systems to provide low-cost energy storage. Developers are keen to move on from major performance issues seen at Crescent Dunes, the world’s first large-scale CSP tower with storage, which dented investor confidence.

Higher temperatures used in CSP tower designs have increased the importance of temperature fluctuations which can reduce efficiency and degrade components. In particular, ‘transient’ plant conditions caused by intermittent sunshine or rapid start-up and shutdown requirements are a key risk for operators, NREL said in its report.

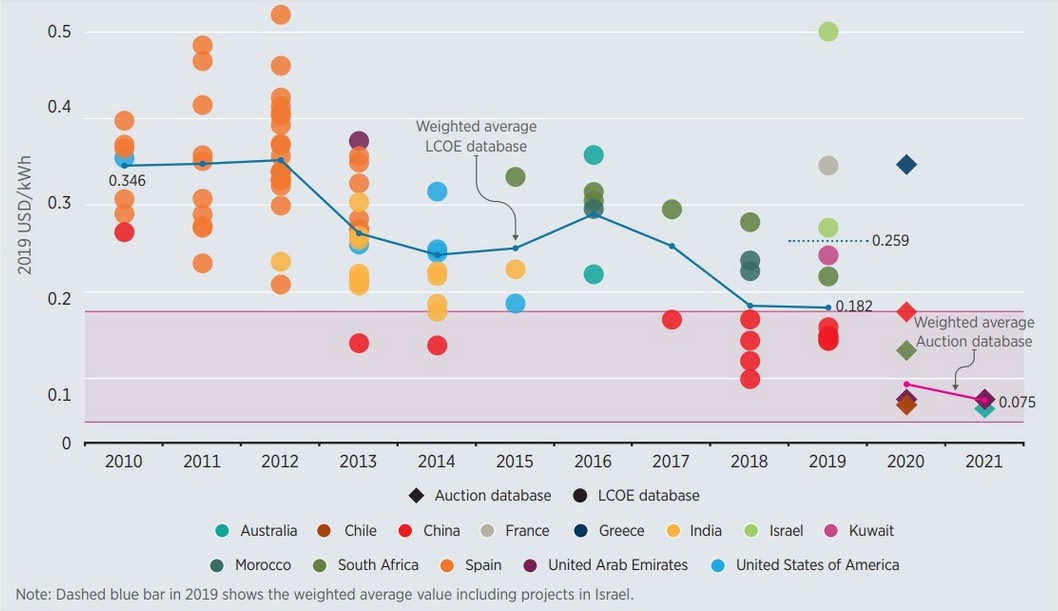

New benchmarks

The failure of SolarReserve’s 110 MW Crescent Dunes tower plant in Nevada highlighted the impact of high-temperature transfer fluids on system structures. Crescent Dunes was brought online in October 2015 but the plant consistently missed performance objectives, leading to the closure of the plant. Issues included an eight-month shut down due to a leak in the molten salt storage system.

In court filings, SolarReserve blamed ACS Cobra, designer of the salt storage tanks, for the leak. ACS declined to comment when contacted by New Energy Update last month.

More information click here

Image credit: International Renewable Energy Agency’s ‘Renewable Power Generation Costs 2019’ report (June 2020).